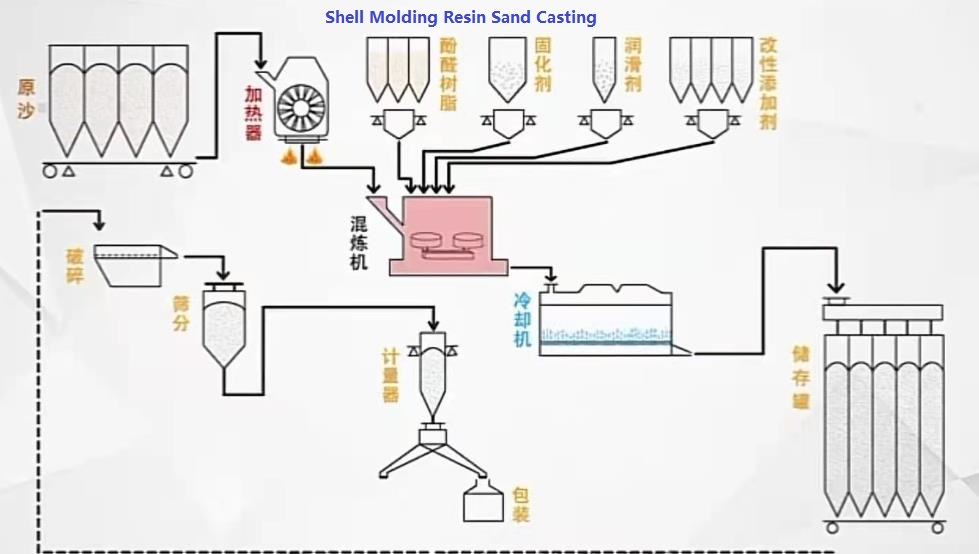

This video in order to introduce the advantages of shell molding sand casting comparing with green sand casting, water glass sand casting (sodium silicate) and resin sand casting (furan resin). 1, shell mold sand has high strength and toughness, good fluidity, low expansibility, suitable for manufacturing complex shell sand core, used in the production of all kinds of complex structure of precision castings. 2, shell mold sand has thermal stability, sand resistance ability is strong, with its production of casting surface finish, high dimensional accuracy, aIt can even match the quality of the castings from the investment casting process. 3, shell mold sand has strong adaptability, can be used for cast iron, cast steel, cast aluminum and other alloys casting. 4, shell mold sand casting process is simple, short process, only shell core manufacturing, molding, pouring, sand cleaning and other four processes, high production efficiency, suitable for the production of small and medium-sized castings in large quantities. 5, shell molding sand casting process with small amount of sand, generally only one third to one quarter of the amount with other sand casting process, low production cost.

Contact: Paul

Phone: +86-15373222406

Tel: +86-13722261532

Company: Baoding Worth Engineering Technology Co., Ltd.

Add: No.31 Chuangye Road, Baoding, Hebei, China.